- Author Isaiah Gimson gimson@periodicalfinance.com.

- Public 2023-12-17 02:53.

- Last modified 2025-01-24 12:06.

The issue of determining the cost of products is the cornerstone of any business. This calculation will determine the size of the start-up capital, as well as the level of competitiveness of the manufacturer. Accordingly, the lower the cost, the larger the corridor in which the price can be determined, and the higher the profit.

Instructions

Step 1

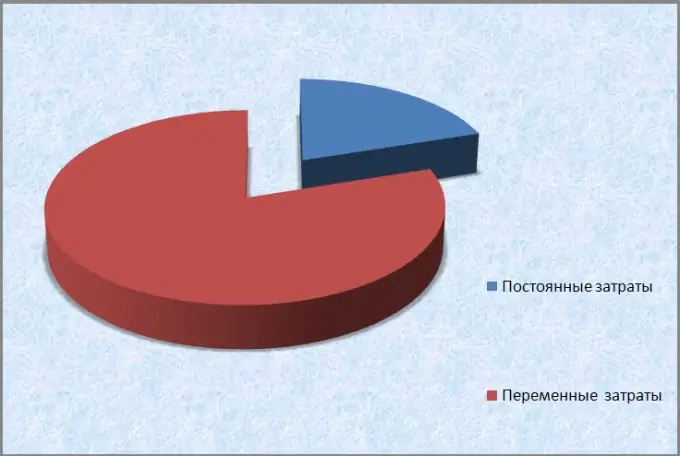

The cost of the final product is made up of variable, fixed costs. At the same time, it is necessary to correctly distribute production costs by type of product and calculate how much the enterprise can successfully sell. The larger the volume, the lower the cost price, because the size of fixed costs does not change. But at the same time, it is important not to cross the point of overproduction, so that the products do not stale, increasing storage costs.

Step 2

Determination of variable costs Variables include those quantities, the size of which changes with a change in the volume of production. First of all, these are materials, piecework wages. Variable costs can also include transportation costs, electricity consumed in the production process, fuel, and so on.

Step 3

Determination of fixed costs Fixed costs do not change in proportion to the volume of products produced. These include the salaries of management personnel, rent, depreciation of fixed assets and equipment, and sales costs. If production requires expansion, then with the introduction of new production facilities, fixed costs also increase.

Step 4

Distribution of fixed costs If an enterprise produces only one type of product, then there will be nothing to distribute - all costs must be invested in its value. But if the assortment is wide, then you need to apply one of the following methods: - by the worked time in hours; - by the production area; By the time of the equipment. As an example, let's say that the production cycle of product A takes 3 hours, and product B - 4 hours … Accordingly, if the number of A and B is equal, then 3/7 of the volume of fixed costs should be attributed to A, and 4/7 to B.

Step 5

Calculation of the volume of products produced As already mentioned, the higher the volume of goods produced, the lower the share of fixed costs in it. In addition to demand and production capacity, the availability of materials, finance, and labor resources can also be limiting factors. Once you have found the optimal output, you can distribute fixed costs and calculate the exact cost per unit of product.